Pay Special Attention to Relief Valve and Flare Piping

- Jul 16, 2025

- 2 min read

Updated: Sep 7, 2025

For safety reasons, flare headers should be routed without pockets and sloped to allow free drainage into the flare knock-out drum. Branch connections to the flare header should be made at the top of the line. When flare header routings contain pockets, liquids can accumulate in the line, resulting in backpressure and potentially creating a hazardous situation. This pocket in the flare header is also subjected to accelerated localized corrosion due to low or no flow and the accumulation of contaminants.

While walking down a project at a client's recently acquired RNG plant, we identified a flare subheader with a major pocket. Operations added the line after the facility was constructed to provide flare relief to equipment outside the process building. Once entering the building, the subheader turns down, runs for a few hundred feet, then turns up, connecting into the bottom of the main flare header.

This existing flare subheader had to be demolished and reinstalled at a higher elevation to eliminate the pocket.

When laying out a process plant during conceptual engineering, one of the first considerations should be the routing of the flare header. The flare header typically sets the elevation of the pipe rack and is located at the highest level of the rack, allowing the line to be sloped and branch connections to be made at the top of the flare header.

Some facilities use lateral outlets at branch connections to the header to reduce turbulence and pressure drop. Lateral outlets add complexity during fit-up and welding due to the angles and weldment geometry.

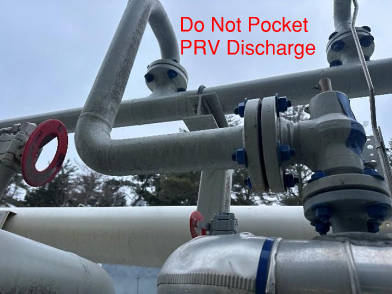

Pressure Relief Valves (PRVs) that discharge into the flare header should be located above the flare line, allowing the PRV tailpipe to be routed into the flare header without pockets. When PRV discharge lines contain pockets, a weep hole or other form of drainage should be provided to prevent liquid accumulation.

When isolation valves are used on the inlet or outlet of a PRV, they should be locked or car sealed open to ensure an open discharge path. When rising stem valves are used for isolation of a PRV, such as gate valves, the valve stem should always be directed horizontally and never vertically upward. There have been instances where the stem separates from the valve assembly while it is oriented upward, causing the stem to fall and close the valve, rendering the PRV useless.